An explosive environment may occur. (Such as: combustible gas, dust environment, oil refinery, petrochemical plant, gas station, gas station, etc.), explosive gas atmosphere, gas, steam or mist-like combustible substance and air mixture, in the mixture After ignition, the combustion will spread throughout the environment of the unburnt mixture. (Such as: CH4, C2H2, C2H4, NH3, CO, C2H5OH and other explosion-proof electrical equipment)

Definition of explosion-proof equipment: electrical equipment that will not cause the surrounding explosive environment to ignite under specified conditions.

Category I: electrical equipment underground in coal mines;

Class II: All other electrical equipment for explosive gas environments except coal mines and underground mines.

Class Ⅱ can be divided into ⅡA, ⅡB, and ⅡC. Equipment marked with ⅡB can be applied to the use conditions of ⅡA equipment; ⅡC can be applied to the use conditions of ⅡA and ⅡB.

Class III: Electrical equipment in explosive dust environment other than coal mines.

Class ⅢA: flammable fly floc; Class ⅢB: non-conductive dust; Class ⅢC: conductive dust.

Maximum surface temperature: The highest temperature reached by any part of the electrical equipment that may cause the surrounding explosive environment to ignite when the electrical equipment is working under the most unfavorable operating conditions within the specified range. The maximum surface temperature should be lower than the combustible temperature.

For example: the ignition temperature of the explosive gas in the explosion-proof sensor environment is 100℃, then the highest surface temperature of any part of the sensor should be lower than 100℃ under the worst working conditions.

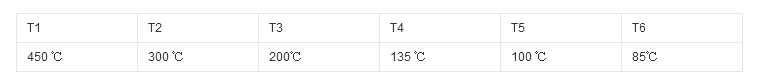

Electrical equipment used in explosive atmospheres is divided into groups T1-T6 according to its maximum surface temperature

1. The IEC / CENELEC / EUrOPE and NORTH AMERICA / FM standards are often used, while the CANADA / CSA standards are almost not used in China.

Example: CENELEC: Eex de/Eex d ib IIC T2-T6

FM: NI/I/Z/ABCD DIP/II, III/1/EFG

XP/I/1/ABCD DIP/II, III/1/EFG

CSA: Class I, Div 2, ABCD

2. The new European explosion-proof standard ATEX100a will replace the original CENELEC standard (as of 2003)

ATEX 100a: II IG Eex ia IIB T6

I II 1G Zone 0 1D, 2D,3D dust explosion

Mining other 2G Zone 1

Industry industry 3G Zone 2

the term

Definition of safety parameters of safety barrier:

*8226; Maximum allowable voltage of safety barrier: Um

Ensure the intrinsic safety performance of the intrinsically safe side of the safety barrier, and allow the highest possible input voltage for the non-intrinsically safe side

*8226; Maximum open circuit voltage of safety barrier: Uoc

The maximum voltage when the intrinsically safe terminal is open within the maximum allowable voltage range

*8226; Maximum short-circuit current of safety barrier: Isc

The maximum current when the intrinsically safe terminal is short-circuited within the maximum allowable voltage range

*8226; Safety barrier allows distributed capacitance: Ca

The maximum allowable external capacitance of the intrinsically safe terminal under the condition of ensuring the intrinsic safety performance

*8226; Safety barrier allows distributed inductance: La

The maximum allowable external inductance of the intrinsically safe side under the condition of ensuring intrinsic safety performance

Explosion-proof mark format description:

The explosion-dangerous medium in the factory or mining area is scientifically classified and classified according to its ignition energy, minimum ignition temperature, and the time period of the on-site explosive hazardous gas to determine the explosion-proof mark and explosion-proof form of the on-site explosion-proof equipment.

Glossary:

ia level: electrical equipment that cannot ignite explosive gas mixtures during normal operation, one failure and two failures.

During normal operation, the safety factor is 2.0; for one failure, the safety factor is 1.5; for two failures, the safety factor is 1.0.

Note: Contacts with sparks must be equipped with flameproof enclosures, air-tight enclosures or double the safety factor.

ib level: electrical equipment that cannot ignite explosive gas mixtures during normal operation and a failure.

In normal operation, the safety factor is 2.0; in case of a fault, the safety factor is 1.5.

During normal operation, spark-proof contacts must be protected by flameproof enclosures or airtight enclosures, and there are measures to self-display failures. The safety factor is 1.0 when a failure occurs.

EExd: refers to the meaning of enveloping the explosion;

IIC: refers to the ignition energy uJ,280,>180,60...80,<60; T6: refers to the temperature group, that is, electrical equipment is divided into different temperature groups according to its maximum surface temperature. The temperature group of the gas is divided into different ignition temperatures. T6 is 85 degrees.

Explosion-proof electrical equipment (d): refers to the electrical equipment that encloses the components that can ignite explosive mixtures in an enclosure that can withstand the explosive pressure of the internal explosive mixture and prevent the explosion of the surrounding explosive mixture.

Increased safety electrical equipment (e): Under normal operating conditions, no spark or dangerous temperature will be generated to ignite explosive mixtures, and structural measures shall be taken to improve its safety level to avoid ignition under normal and prescribed overload conditions Electrical equipment.

Intrinsically safe electrical equipment (i): Electrical equipment that cannot ignite explosive mixtures by sparks or thermal effects generated under normal operation or under standard test conditions.

Non-sparking electrical equipment (n): Electrical equipment that does not produce arcs or sparks under normal operating conditions, nor does it produce high-temperature surfaces or hot spots that can ignite surrounding explosive mixtures, and generally does not cause ignition failures.

Explosion-proof special type (s): When electrical equipment or components adopt explosion-proof types not included in GB3836-2010, the competent authority shall formulate temporary regulations. Submit to the Ministry of Labor and Personnel for the record, and after being inspected by the designated appraisal unit, it shall be disposed of as special electrical equipment "s".

1. Intrinsically safe "i" (intrinsically safe electrical equipment and related equipment) Intrinsically safe circuit:

Under the specified test conditions, neither the electric spark nor the thermal effect produced under the specified fault state can ignite the specified explosive gas or steam circuit.

Intrinsically safe electrical equipment: All circuits are intrinsically safe electrical equipment.

The intrinsic safety of intrinsically safe equipment and associated equipment is divided into ia and ib:

¨ ia: Normal operation + one fault + two faults in any combination can not cause ignition of electrical equipment.

¨ ib: Normal operation + an intrinsically safe electrical equipment that cannot cause ignition under a fault condition.

This shows that the ia level is higher than the ib level

Associated equipment: electrical equipment equipped with intrinsically safe circuits and non-intrinsically safe circuits, and the structure is such that the non-intrinsically safe circuits cannot adversely affect the intrinsically safe circuits.

2. Flameproof type "d" Electrical equipment with flameproof enclosure.

It can withstand the internal explosion of the flammable mixture that has entered the shell without being damaged, and it will not ignite the electrical equipment in the external explosive environment formed by one or more gases or vapors through any joint surface or hole on the shell. shell.

3. Increased safety e

4. Oil-filled o

5. Sand-filled q

6. Encapsulated type m

7. Compound

KNLB-EX30(30W)

ATEX Horn Speaker

KNSIPSP-L4(7w)

IP Speakers

.jpg)

KNEX5

Ex telephone

.jpg)

KNSP-01

Weatherproof telephone

Thank you for reading, if you have any questions or needs, please contact us!

EMAIL: marketing@koontech.com, we will reply you immediately

Previous:Analog telephone